Technical White Paper of AILEIKE Portable Air Pressure Pump ALKB9602

Technical White Paper of AILEIKE Portable Air Pressure Pump ALKB9602

Ⅰ. Product Overview and Technical Background

The ALKB9602 portable air pressure pump is a high-precision portable air pressure generating device designed specifically for laboratory and field pressure instrument calibration. As an important auxiliary equipment in the field of pressure calibration, it is used in conjunction with pressure gauges to complete pressure instrument calibration and testing work, and is a key tool in pressure instrument testing work. The product adopts an open design, which features simple operation, effortless operation, stable pressure rise and fall, low leakage, and easy maintenance, providing reliable guarantee for the precise calibration of pressure instruments.

Ⅱ. Technical parameters and performance indicators

2.1 Basic Technical Parameters

|

Parameter category |

Technical indicators |

Remarks |

|

Usage environment |

Laboratory or on-site |

Adapt to different work scenarios |

|

Ambient temperature |

0~50℃ |

Wide temperature working range |

|

Relative humidity |

<80% |

Moisture resistant design |

|

Pressure range |

-0.095~6MPa |

Covering positive and negative micro pressure requirements |

|

Measuring medium |

Clean air |

Good media compatibility |

|

Pressure output |

2 of them |

Can simultaneously connect the standard table and the inspected table |

|

Threaded interface |

M20×1.5 or user specified |

Flexible interface configuration |

|

Regulating fineness |

Min 10Pa |

High precision pressure regulation |

|

Overall dimensions |

320×200×160mm |

Lightweight design |

|

Weight |

3.2kg |

Portable |

2.2 Core Performance Characteristics

Easy to operate: The product adopts an intuitive operating interface, with a reasonable layout of pressure rods, positive and negative pressure switching valves, fine adjustment valves, and shut-off valves, and a simple and clear operating process. Operators only need to follow the standard operating procedures to easily complete pressure calibration work.

Multifunctionality: Supports switching between positive and negative pressure, meeting calibration requirements for different pressure ranges.

Precise pressure control: The adjustment fineness can reach 10Pa, far exceeding the industry average level, ensuring the accuracy of pressure control.

Convenient design: Portable design, weighing only 3.2kg, with external dimensions of 320 × 200 × 160mm, easy to carry and operate.

Quick interface design: equipped with two standard M20 × 1.5 pressure quick connection ports, convenient for quick connection with standard and tested meters, improving work efficiency.

Ⅲ. Main application areas

1. In the field of metrology calibration:

As an auxiliary equipment for pressure standards, it is used for calibration and testing of various pressure instruments.

2. Medical field:

Can be used to calibrate pressure sensors in medical equipment, such as ventilators, to ensure the accuracy and safety of medical devices.

3. Industrial and mining enterprises:

Used for pressure detection, equipment maintenance, and quality control in industrial sites.

4. Instrument manufacturing:

Used for product calibration and quality testing in the production process of pressure instruments.

5. Research and Education:

6. Laboratories in higher education institutions and research institutes are used for research and teaching experiments related to pressure measurement.

Ⅳ. Operation and Maintenance Guide

Operating process

Pressure verification

First, connect the tested meter to the interface of the tested meter and the standard meter to the interface of the standard meter. Rotate and press the switch valve knob to open the shut-off valve. Rotate the fine adjustment counterclockwise to close the pressure relief valve. Use a hand pump to pressurize to about 3.5-4.0 MPa, then close the shut-off valve and use the fine adjustment to pressurize to the desired pressure. When releasing pressure, first open the pressure relief valve, and then open the shut-off valve.

Vacuum calibration

First, connect the tested meter to the output of the tested meter and the standard meter to the interface of the standard meter. Rotate and pull out the switch valve knob, open the shut-off valve, turn the fine adjustment clockwise, close the pressure relief valve, and use a hand pump to draw pressure to the desired vacuum value. When releasing pressure, first open the pressure relief valve, and then open the shut-off valve.

Precautions

1. The device should be used within the rated pressure range as much as possible and should not be used beyond the range.

2. The pressure/vacuum conversion must be carried out in a non pressure state.

3. The calibration table should be placed on a stable operating platform to avoid entering environments with corrosive gases and dust particles.

4. If not used for a long time, the equipment should be stored in a dry, non corrosive gas environment.

5. Leverage pressure, apply even force, do not use force when closing or opening the valve.

6. Regularly clean the impurities inside the filter to prevent them from affecting the service life of the equipment.

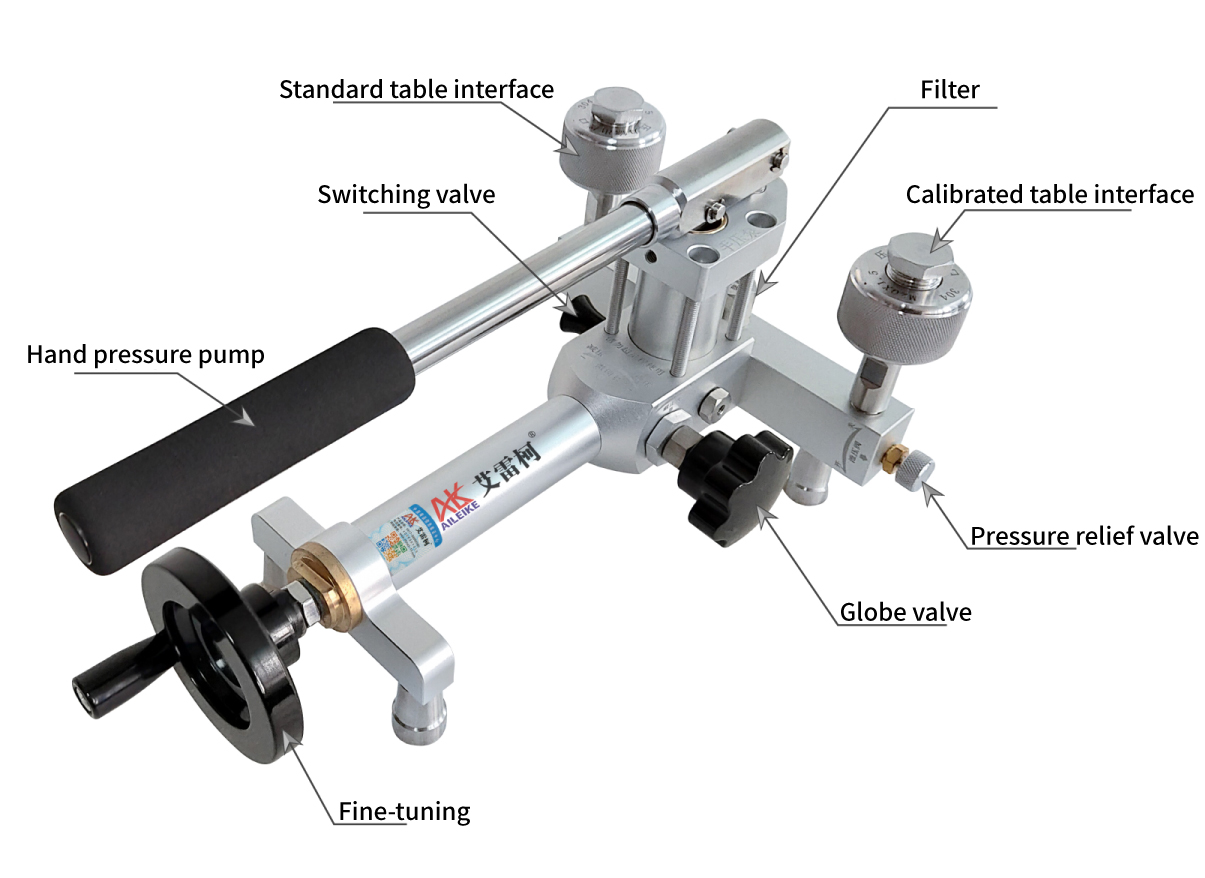

Ⅴ. Structural Function

Ⅵ. Conclusion

The pressure range of ALKB9602 is one of its most significant technical indicators. This product can provide stable pressure output within a wide range of -0.095-6MPa, covering a wide range of application scenarios from micro negative pressure to medium pressure. This range can meet the calibration needs of the vast majority of pressure instruments, including calibration and verification of equipment such as pressure gauges, pressure transmitters, pressure sensors, and pressure switches. Effectively solving the pain points of cumbersome operation, poor sealing, and insufficient portability of traditional air pressure pumps, it provides efficient and reliable pressure calibration solutions for industrial automation, energy industry, medical field, and measurement and testing institutions.

English

English Portuguese

Portuguese  Indonesian

Indonesian  Russian

Russian  Arabic

Arabic